Barn Owl

Name |

Barn Owl |

Price (Ex Vat) |

£18,999 |

External Dimensions (W x L x H) |

2.55m x 5.85m x 2.5m |

Internal Dimensions (W x L x H) |

2.1m x 5.4m x 2.1m |

Internal Area |

11.34m2 |

Number of Boxes |

66 |

The Barn Owl is long and slim like a traditional Shepherds Hut, which means there is enough room for a small kitchenette, a double bed and even a separate shower room. There a great variety of internal configurations and uses – enough room to store bikes, music equipment, paints and much more. The Pine Marten would suit a wide garden, where it could sit across the back of the space, or a long and narrow garden, where it could nestle up on one boundary and leave room to pass by on the other side. We can help you customise the space by changing window and door positions, adding internal walls and doors, shelving and storage or rooflights.

Here is a summary of the key characteristics of the design, including an explanation of how to make sure it fits within your space. If you want to dive any deeper please feel free to visit our FAQs page for more juicy chunks of information.

Sizing

Read More About Sizing

- The U-Build system are designed to a 0.3m internal grid, which makes it really easy to fit in standard doors and furniture.

- Our typical external walls are 0.225m in width, made up of 0.15m insulated boxes and 0.075m external cladding material.

- If you measure the size of your space and subtract 0.4m from each boundary, that will tell you the biggest size pod that will fit, whilst still allowing some access for maintenance.

- Our smallest U-Buildings are 2.5m in height which means that they can meet UK permitted development height, depending on your ground levels.

- Rooflights add an additional 0.15m, so these would not usually meet UK permitted development height.

- Our internal height of 2.1m is only to the bottom of the roof beams. In between the beams the height is actually 2.23m. Bonus!

- Typical pods are 0.15m off the ground and have a 0.15m floor construction. So your finished floor will be 0.3m from the ground.

U-values

Read More About U-values

All our U-Buildings have a wall U-Value of 0.3W/m2k as standard which makes them suitable to use all year round. If you want your building extra cosy we have an option for double thickness walls which can improve the U-Value to Passive House levels of 0.15W/m2k.

We also think it’s great cool that U-Values are completely on brand with U-Build! It’s like we did it on purpose … except we didn’t.

Air tightness

Read More About Air tightness

We have carried out an air tightness on one our U-Buildings and achieved air-tightness levels of 2m3/hr/m2 @50Pa. This was 4-5 times better than current building regulations even before any airtightness membrane was used! With the addition of the external membrane, our build ups can meet Passive House levels of airtightness, which we think is pretty good.

Windows & Doors

Read More About Windows & Doors

We can incorporate a glazing system of your choice, or provide double glazed, plywood framed windows and doors as a flat pack. We think the plywood kit windows and doors are a great cost effective solution, but are not certified to any given performance standard, so let us know if you have any particular requirements.

U-Build is a sustainably minded company and we believe that good buildings should make both people and the planet happy! All our materials are chosen for their performance and their sustainability, and our boxes are designed to come apart again so they can have many lives.

Boxes & fixings

Read More About Boxes & fixings

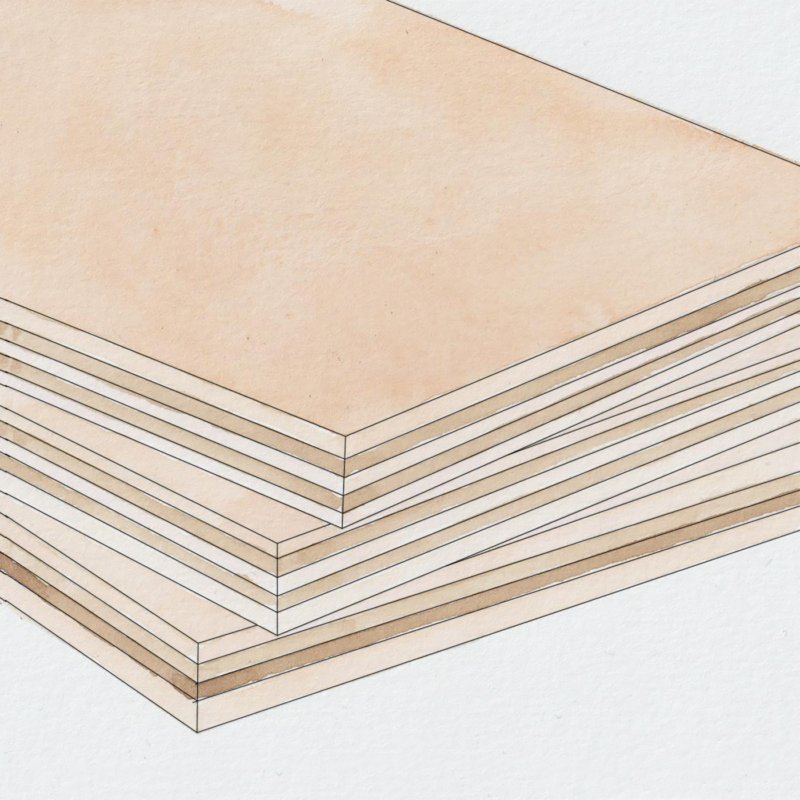

Our structural boxes that create the walls, roof and floor are made from 18mm WISA Spruce plywood as standard, this is FSC certified and PEFC rated. Click here to see a typical Spruce sheet.

Or you can upgrade to WISA Birch, a harder wood (and heavier) option but with a less knotty aesthetic. See here for an example.

To fix the boxes together we will supply you with zinc plated bolts, nuts, screws and washers, as well as stainless steel wood screws.

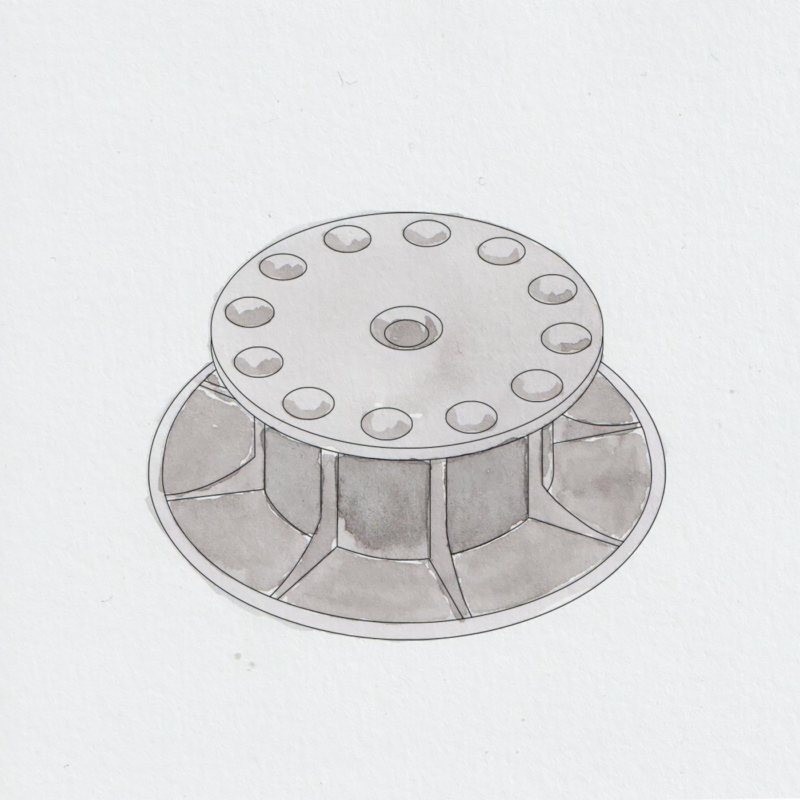

Your pod will be supported by our specialist, height-adjustable decking risers. Each foot can support up to 1 tonne. They are made from 90% recycled plastic and fully recyclable.

Insulation

Read More About Insulation

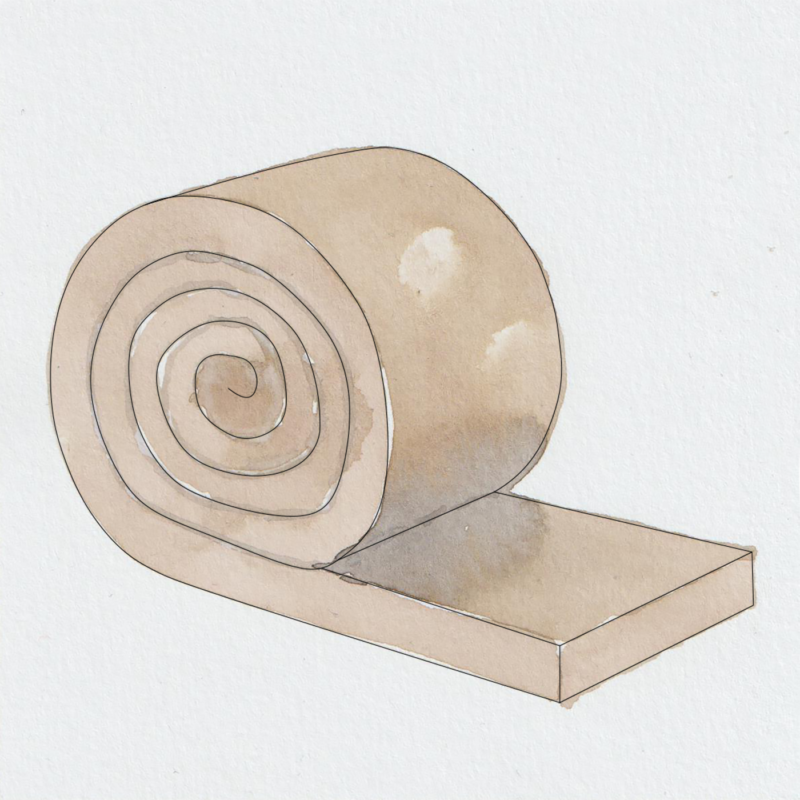

To keep you warm and cosy we provide sheep’s wool, selected for being British based, a natural and breathable eco-friendly insulation for the walls and floor. It is building regulation compliant, contains a borax based fire retardant and does not require the addition of an insecticide. We can also use wood fibre (or most other insulation types).

To insulate the roof, we use a PIR insulation board, chosen for its high performance within 2.5m permitted development height. If you are willing to make the building slightly higher, we can swap this for a wood fibre board.

Membranes & Tapes

Read More About Membranes & Tapes

A damp-proof membrane functions like a raincoat; it will keep you the rain out whilst also allowing moisture to breathe.

For the walls and floor, we use a UV stable and fire rated membrane from Illbruck.

For the roof Butyl membrane; a UV-stable, non-toxic and has a working life of up to 50 years with a 20 year supplier guarantee. An added bonus is that this arrives green roof ready, so you can add your plant layer straight-away.

Cladding

Read More About Cladding

Cladding is the material that you see on the exterior of your U-Building. It acts as a ‘rain screen’ to protect the waterproof membrane behind from damage, and completes the external appearance.

You can use any cladding you like with U-Build, but to make things simple we supply Western Red Cedar, Douglas Fir or Larch depending on availability. We choose UK grown timber with a durability class of 3, an estimated life expectancy of 15-30 years above ground, plus it looks and smells beautiful. We use 45x25mm strips that arrive as linear lengths to be cut down to length on site.

If you would like to install the cladding in a ‘herringbone’ or ‘chevron’ pattern we have a developed a cladding panel making workflow for you to follow.

Cladding panels means that no screws are visible on the front face, and the panels are easy to take off individually for maintenance. Our in house developed software (known affectionately as AutoCLAD) works out the number, length and shape of the different parts and creates a cutting list, which are either be sent for you / carpenter to produce from scratch or cut to length here. To keep the ‘U’ in U-Build, we encourage people to try assembling the panels, and you can also buy one of our specially designed cladding jigs to help with this.

If you like this style but are conscious of time and budget, one idea to save time and costs is to use herringbone cladding for the front only, and use horizontal timber for the back and sides.